China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

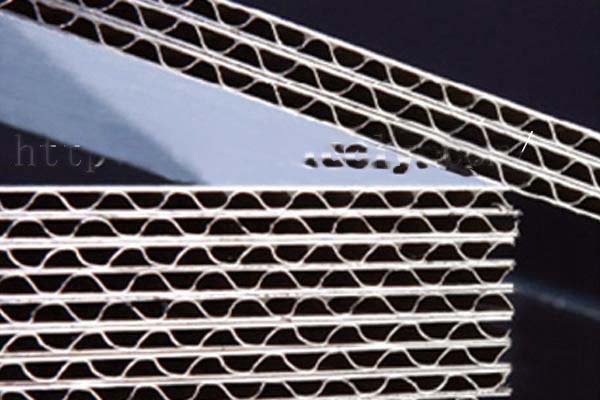

corrugated composite aluminum plateThe finished product has the advantages of light weight, high strength, no deformation, good rigidity, strong cushioning performance, good sound insulation and heat insulation effect. After proper treatment, it can be flame retardant, moisture-proof, waterproof and has lower requirements for raw materials than honeycomb cardboard. Waste paper and old corrugated boxes that can be recycled are used as raw materials for production, so the source of raw materials is wide and sufficient. The finished product can be recycled after use, which meets the environmental protection requirements of resource recycling and has a very wide application prospect.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Since its birth, aluminum curtain wall has been favored by designers for its unique texture, rich color, excellent plasticity, diversity of forms and weather resistance. Its utilization rate in modern architecture is more and more sought after by people, which is a leap in building decoration.

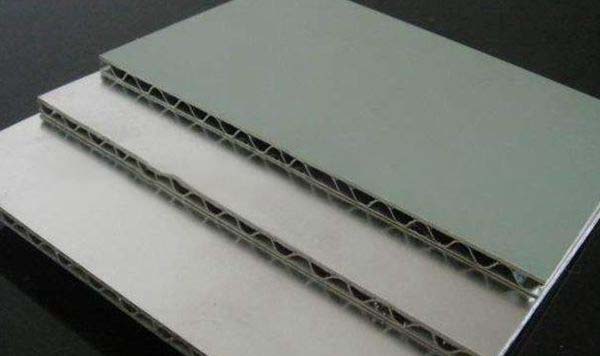

Corrugated composite aluminum plate is installed in the form of aluminum curtain wall for building exterior decorative panels, which can be used in any building, any height, any part, any structural form of high-rise buildings.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

In this way, it breaks the restriction that high-rise buildings and super high-rise buildings cannot use certain decorative panels for exterior decoration. Aluminum curtain wall curtain wall has become a symbol of modern architecture.

The installation process and method of corrugated composite aluminum plate are consistent with the installation and construction process of aluminum-plastic plate, so the installation process and technology are easier. Aluminum veneer needs to be transported to the site after processing in the factory, and it needs to be processed and delivered from the factory in case of breakage. Corrugated composite aluminum plate can be transported to the site for on-site processing, which has obvious advantages for buildings with complex shapes.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Because of its good plasticity, it can better adapt to the requirements of various architectural shapes, but compared with the service life, aesthetic degree and durability and other performance color steel corrugated board is better.

Recommended:Corrugated aluminum plate processing matters needing attention introduction