China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum honeycomb perforated acoustic panelIt is a new type of material with large surface, high flatness, high strength, light weight, good sound absorption effect, fireproof, waterproof, and easy installation. Each board can be disassembled and replaced separately.

Aluminum honeycomb perforated sound-absorbing board features:

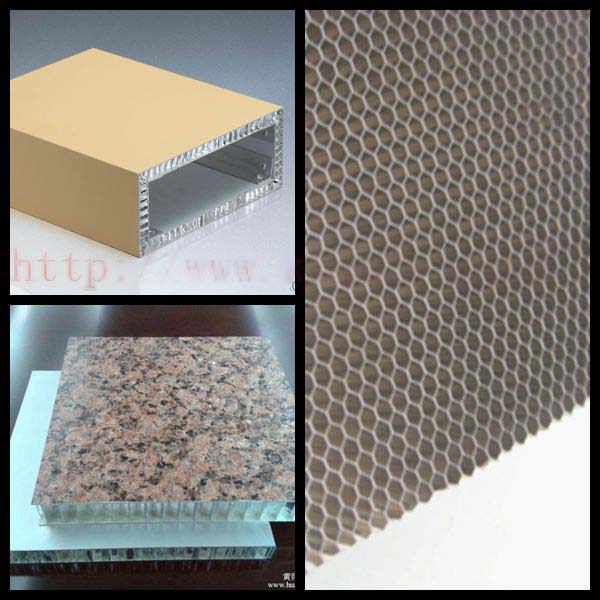

The structure is a perforated panel and a perforated backplane, which are directly bonded to the aluminum honeycomb core by high-quality adhesive to form an aluminum honeycomb sandwich structure, and a layer of sound-absorbing cloth is pasted between the honeycomb core, the panel and the backplane.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, tunnel corridors, etc.

Because the honeycomb core in the honeycomb aluminum plate is divided into many closed cells, the air flow is prevented, the sound wave is hindered, the sound absorption coefficient is improved (more than 0.9), and the strength of the plate itself is improved, so that the size of the single plate can be larger, and the design freedom is further increased.

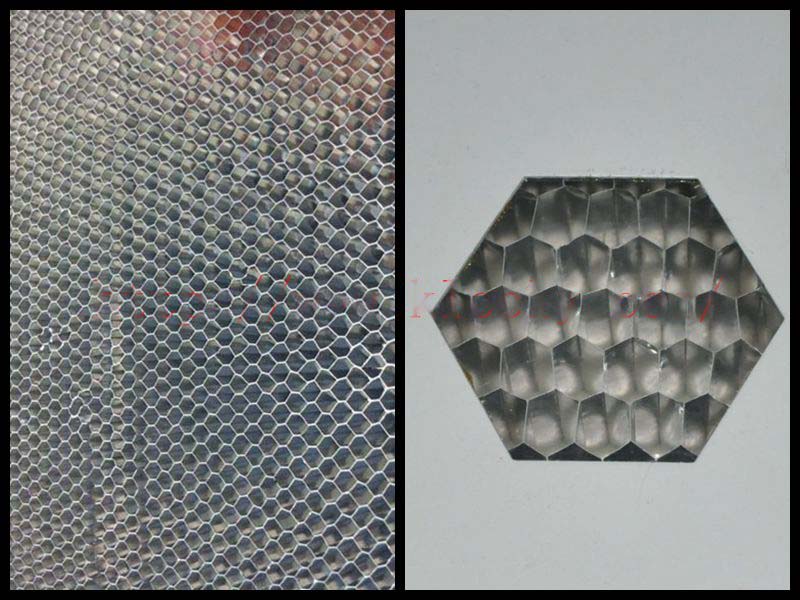

According to the indoor acoustic design, different perforation rate design can be carried out, and the sound absorption coefficient of the combined structure can be controlled within a certain range, which not only achieves the design effect, but also can reasonably control the cost.

By controlling the perforation aperture and hole spacing, the perforation rate can be changed according to the customer\'s use requirements. the maximum perforation rate is less than 30%. the aperture is generally selected from #2.0, #2.5, #3.0 and other specifications. the perforation requirements for the back plate are the same as those for the panel. the sound-absorbing cloth is made of high-quality non-woven fabric and other sound-absorbing materials.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

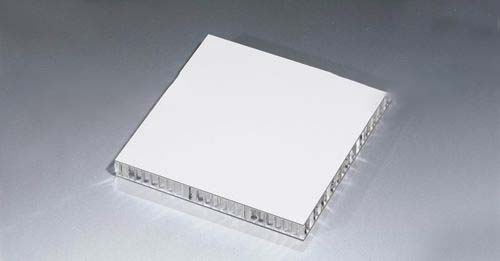

1. Large board surface and high flatness

2. High strength and light weight of the plate

3. Good sound absorption effect, fireproof and waterproof

4. Easy to install, each board can be disassembled and replaced separately

5. The size, shape, surface treatment and color can be customized according to customer needs to meet the individual needs of customers

stainless steel honeycomb plateEasy and fast installation.

aluminum honeycomb panelPerforated acoustic panel installation

First type, installation of lifting lug type acoustic panel

This method is the separation of the lifting lug and the honeycomb plate, the lifting lug after separate processing connection and the position of the glue seam of the honeycomb plate, the appropriate width of the glue seam is greater than or equal to 12mm, this installation method is more simple and convenient to process.

The second, flanged sound-absorbing board installation

This installation method is mainly used when processing aluminum honeycomb panels, that is, processing with flanging for installation. The installation only needs to be connected with the keel and glue seam. The suitable glue seam width is greater than or equal to 10mm. This method is convenient and simple to install, but the processing process is a bit complicated and is not suitable for modeling curtain wall panels.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Recommended:Main features of stainless steel honeycomb density board