China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Porcelain honeycomb aluminum plateThe installation shall be in place according to the plate number on the plate distribution drawing, the installation angle code of the gelatin seam part shall be assembled, and check whether the angle code of the adjacent two plates is staggered, and check the levelness and verticality of the trial assembly, then assemble with stainless steel bolts, try to fix it on the main and auxiliary keels, adjust the horizontal and vertical seam clearance to meet the requirements, and then fix it.

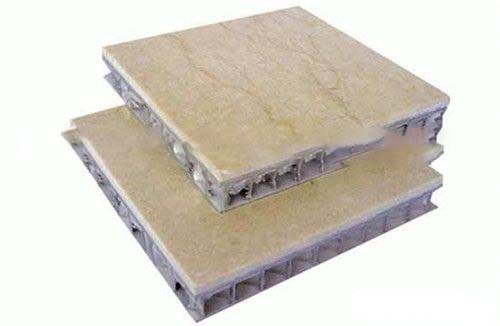

Honeycomb aluminum plate is a composite material with large surface formed by hot pressing and compounding of high-grade aluminum alloy panel, back plate and aluminum honeycomb core material. The product specifications are various, and the surface can be embossed, mirror, embossed, wire drawing, electroplating, anodic oxidation, matte, bright light and metallic color, etc., which can meet the application requirements of various places.

Honeycomb aluminum plateIt is a new type of composite material with sandwich structure, which is composed of two layers of aluminum sheet and aluminum honeycomb core through adhesive. The panel of honeycomb aluminum plate is usually sprayed with fluorocarbon coating or polyester coating. The fluorocarbon coating is widely used outdoors because of its good weather resistance and self-cleaning, and the polyester coating is mostly used indoors.

The quality of porcelain honeycomb aluminum plate is not only related to the selected material, but also depends on the bonding quality, and its key technical index is peel strength. The factors affecting the peel strength of the honeycomb aluminum plate will be described below.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

The bonding strength of honeycomb aluminum plate produced by ceramic honeycomb aluminum plate using thermoplastic film continuous composite process is 3-5 times that of honeycomb aluminum plate produced by the first two processes. For honeycomb aluminum plate with regular hexagonal honeycomb core side length of 4mm, panel thickness of 1mm and total thickness of 10mm, the measured 180 peel strength value is about 18N/mm. Its adhesion and weather resistance are good, and its peel strength decreases little after 1 year of use.

The installation of porcelain honeycomb aluminum plate column shall first connect the column with the connecting piece, and then connect the connecting piece with the embedded part of the main body, and adjust and fix it. The installation elevation deviation of two adjacent columns shall not be greater than 3mm, the maximum elevation deviation of columns on the same floor shall not be greater than 5mm, and the distance deviation of two adjacent columns shall not be greater than 2mm.

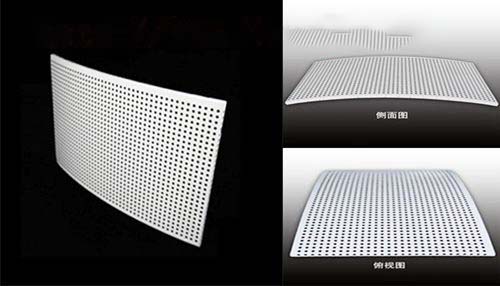

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Porcelain honeycomb aluminum sheet is composed of aluminum veneer, sandblasting surface treatment layer and a layer of inorganic coating layer. It is made of high-grade aluminum alloy as the main material and processed and formed by sheet metal workshop through various processing techniques. It is a kind of building interior and exterior wall decoration material with superior performance.

Recommended:Related Knowledge of Laminate Floor Buckle