China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

随着Aluminum Honeycomb Panel FurnitureWith the continuous development of the industry, a full-automatic honeycomb paper core and honeycomb paperboard continuous production line has been designed. More and more new styles of furniture appear in front of us.

However, when consumers buy furniture, they pay more attention to not only the style of furniture, but also whether the furniture is environmentally friendly and whether it will affect their health. Therefore, environmental protection furniture is gradually being valued by people, so the honeycomb panel furniture also came into being.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

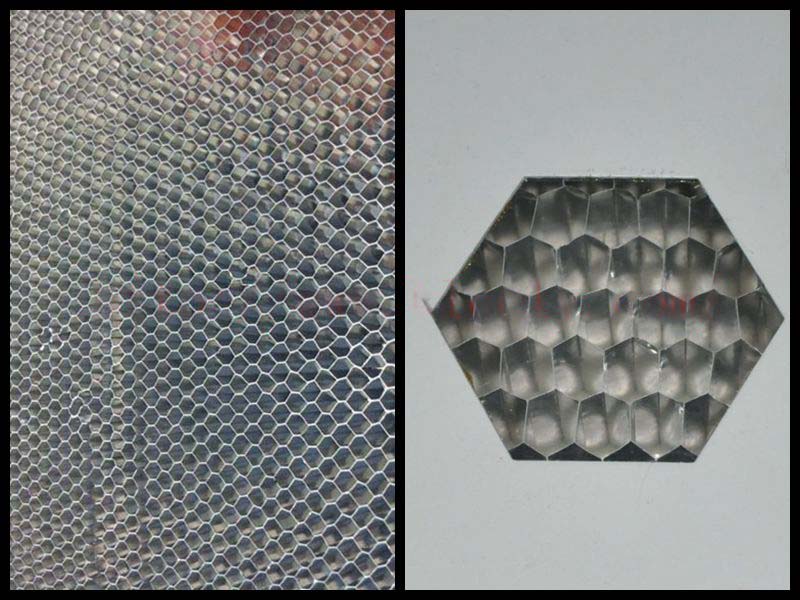

The aluminum honeycomb panel is a honeycomb sandwich panel with a honeycomb structure as the core layer, and the aluminum honeycomb panel furniture is inspired by the natural hexagonal honeycomb. Aluminum honeycomb panels made of aluminum alloy because of its unique structure not only in the same volume of other materials in the lightest quality, and stiffness and overall stability are very good, but also has sound insulation and heat insulation performance.

Aluminum alloy is not radioactive, will not volatilize any harmful gases harmful to human health, but also can be completely recycled and reused, saving resources and energy, the pollution to the environment to a minimum level, which makes aluminum honeycomb panels become a new material for energy saving, environmental protection and health.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

The inner layer is a special hexagonal aluminum honeycomb, and the aluminum honeycomb panel furniture is composed of aluminum alloy with a hardness of H19. As a core plate adhered to the sandwich structure, it bears pressure in the tangential direction. These mutually restrained dense honeycombs are like many small I-beams, which can be dispersed to bear the pressure from the direction of the panel, so that the plate is evenly stressed and ensures that the panel can still maintain a high flatness in a large area.

Installation method of aluminum honeycomb panel

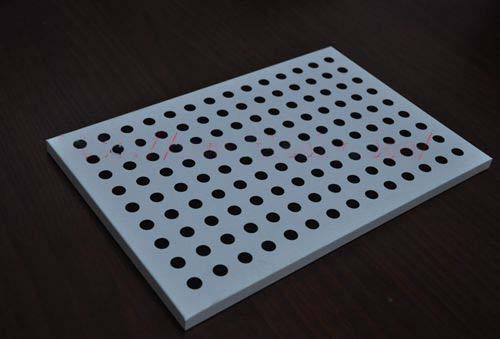

1. Lug type

This installation method is to separate the lifting lug and the honeycomb panel. After the lifting lug is processed separately, it is connected to the glue seam position of the honeycomb panel. The suitable width of the glue seam is ≥ 12mm. This installation method makes the processing simple and the installation convenient.

stainless steel honeycomb plateEasy and fast installation.

2. Flip type

This installation method is to process the flanging for installation when processing the aluminum honeycomb panel. The installation only needs to comfort the connection with the keel and glue seam. The suitable glue seam width is ≥ 10mm. This method is convenient to install, but the processing is slightly complicated and is not suitable for modeling curtain wall panels.

Recommended:Aluminum honeycomb panel ceiling installation method