China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Installation of aluminum honeycomb panelMethod and installation of auxiliary materials

1. Lug type

This installation method is to separate the lifting lug and the honeycomb panel. After the lifting lug is processed separately, it is connected to the glue seam position of the honeycomb panel. The suitable width of the glue seam is ≥ 12mm. This installation method makes the processing simple and the installation convenient.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

2. Flip type

The installation method of aluminum honeycomb panel is to process the flanging for installation when processing the aluminum honeycomb panel. The installation only needs to comfort the connection with keel and glue seam. The suitable glue seam width is ≥ 10mm. This method is convenient to install, but the processing is slightly complicated and is not suitable for modeling curtain wall panels.

3. Buckle type

This node is aluminum buckle strip type, buckle strip is a specific profile, easy to install, but this method requires high machining accuracy of the plate, it is not recommended to use the length of more than 3000mm plate. According to the width of the buckle strip, the plate is sewn with 20mm and 40mm, etc.

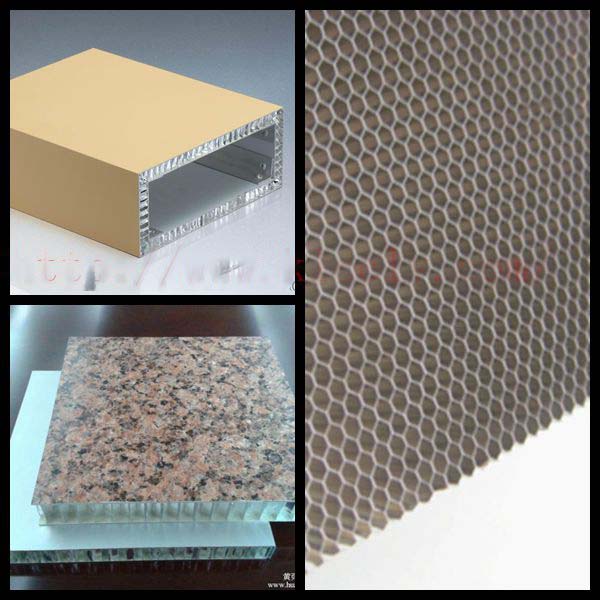

aluminum honeycomb panelIt is suitable for civil buildings, vehicle and ship decoration, etc. It is the application of aviation and aerospace materials in the field of civil construction.

stainless steel honeycomb plateEasy and fast installation.

The whole processing process is completed in a modern factory. Hot pressing technology is adopted. Due to the high thermal conductivity value between the aluminum skin and the honeycomb, the thermal expansion and contraction of the inner and outer aluminum skin are synchronized. There are small holes in the honeycomb aluminum skin, so that the gas in the plate can flow freely. The slidable installation buckle system will not cause structural deformation during thermal expansion and contraction.

Because the honeycomb material has high wind pressure resistance, shock absorption, sound insulation, heat preservation, flame retardant and high specific strength. In the 1960 s, foreign countries have been used in various fields of civil use, and have developed rapidly. In recent years, cellular technology has been applied in various fields of civil industry.

Aluminum honeycomb panel curtain wall with its light weight, high strength, stiffness and many other advantages, has been widely used in high-rise building exterior decoration. The aluminum honeycomb panel with a total thickness of 15mm and a panel floor of 1.0mm is only 6Khg/㎡.

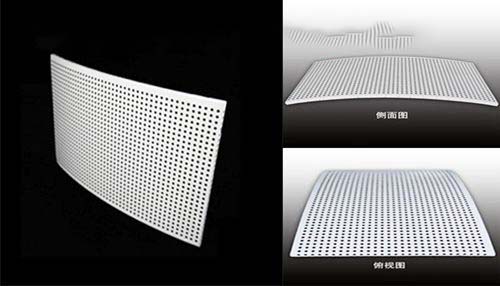

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Honeycomb panels with the same stiffness weigh only 1/5 of aluminum veneer and 1/10 of steel plate. The aluminum honeycomb core connected with each other is like countless I-beams. The core layer is distributed and fixed in the whole plate surface to make the plate more stable. Its wind pressure resistance is much higher than that of aluminum veneer and aluminum veneer. It is not easy to deform and has good flatness, even if the cell size of the honeycomb plate is very large. It can also achieve extremely high flatness and is currently the preferred lightweight material for the construction industry.

Recommended:Honeycomb Aluminum Panel Installation