China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

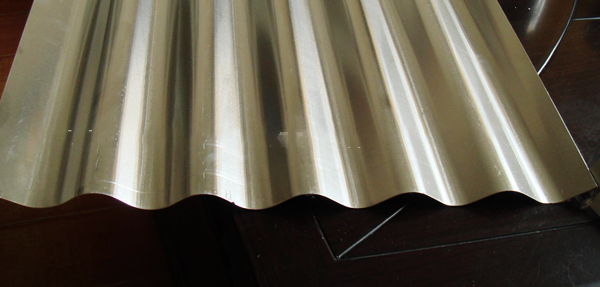

860 type corrugated aluminum plateIt is one of the commonly used Products in construction, and there is a trend to replace stainless steel and iron plates. First of all, because the density of aluminum is only 2.71 and the density of iron is 7.8, the weight of each square aluminum tile is less than 1/3 of that of stainless steel, which can reduce the cost of the enterprise and reduce the pressure of the bracket.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

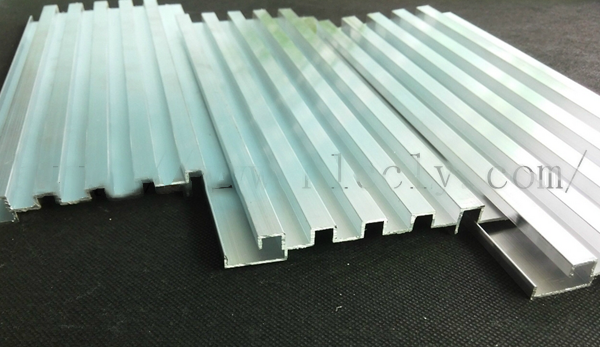

Corrugated composite aluminum plate is a new type of composite aluminum plate curtain wall material made of corrugated aluminum plate with 0.6-0.8mm plate, 0.4mm plate and 0.2mm plate in the middle. The surface of corrugated core material is coated with thermosetting epoxy resin adhesive and heated and pressurized. The composite method is similar to the form of corrugated cardboard box board.

Corrugating rollers and pressure rollers must have a more reasonable and consistent line pressure of medium height accuracy. The height of the micro-corrugated is very low, and the wear of the corrugated high is more than 0.1mm, which will affect the product quality. For the micro-corrugated corrugated roller, more wear-resistant surface layer quality is required.

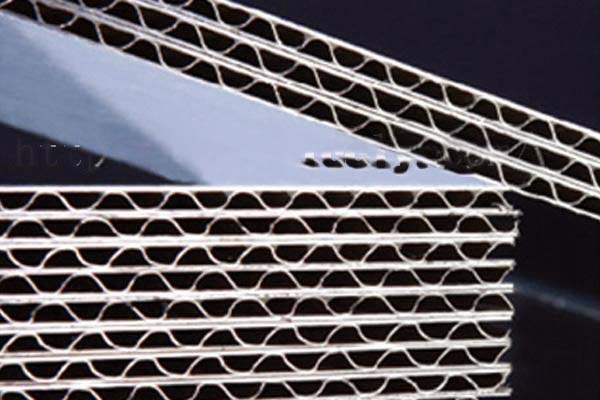

stainless steel honeycomb plateEasy and fast installation.

Corrugating roller and pressure roller must have uniform wall thickness, 860 type corrugated aluminum plate after heating to maintain the accuracy of cylindricity, but also have a reasonable condensate water discharge system structure design, to ensure that the corrugated roller is not due to the bottom of the roller water temperature difference between the upper and lower bending deformation.

At the same time, the angle of the corrugated structure should meet the sufficient rigidity and mechanical strength of the micro corrugated board. The corrugated surface of the micro-corrugated corrugated roller needs higher roughness requirements, and must be finely ground and polished, and the 860 corrugated aluminum plate can ensure the high-speed molding of corrugated base paper with light weight and low strength.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

It can be seen that the tension during paper feeding and molding increases exponentially. Therefore, the design of the stare blankly type must ensure that the angle value of the stare blankly type is within the strength of the corrugated base paper, and the selection of the arc at the top of the stare blankly type must make the entry resistance of the corrugated base paper smaller, smoother and smoother.

Recommended:What is the performance of Changzhou wood floor composite fastener