China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

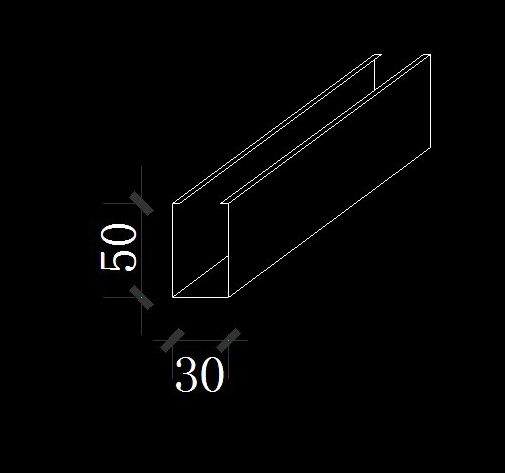

1. material requirements: 1. Material: The material selection of aluminum veneer shall conform to the provisions of GB/T5237 Aluminum Alloy Building Profiles, and the commonly used material type is 3003H24; The thickness of aluminum veneer to be used in this project is 3mm. 2, coating: fluorocarbon paint coating, coating times shall not be less than two, the thickness should be greater than 25μm; and fluorocarbon resin content should not be less than 75%; fluorocarbon coating should be free of blisters, cracks, peeling and other phenomena. 3. Processing, storage and handling: The stiffening ribs and connecting parts of aluminum veneer can be welded and riveted, and the positions should be accurate and firm. The surface layer of aluminum veneer shall be pasted with a polyethylene plastic protective film with a thickness of not less than 0.3mm, and the inner and outer surfaces of aluminum veneer shall not be scratched. 4. Allowable deviation of aluminum veneer processing size: unit (mm)

Read more

Aluminum honeycomb plate glue, also known as polyurethane glue, is used for the bonding of color steel plate, aluminum plate and aluminum honeycomb. It is one of the essential raw materials for the production of manual purification board and exterior wall insulation and decoration materials.

Read more

Although the honeycomb aluminum curtain wall has many advantages, but in the practical application will produce some problems, the main problem is reflected in the following two aspects: (1) aluminum curtain wall panel deformation (drum); (2) aluminum curtain wall insulation energy saving.

Read more

Aluminum honeycomb panel is a new aluminum honeycomb composite panel, it overcomes the traditional honeycomb bonding layer brittleness, low tear resistance and impact resistance, poor processability, high cost shortcomings, can be applied to the production of aluminum honeycomb curtain wall panel, which created a new situation in the application of aluminum honeycomb panel market.

Read more

Compared with aluminum veneer, the maximum plate surface of box-type honeycomb aluminum plate can be 1500mm × 4500mm, because the plate itself is made of composite material, and the internal aluminum honeycomb provides guarantee for the plate itself to bear its own weight.

Read more

The process of aluminum honeycomb panel generally adopts continuous roller coating, and the surface painting is completed at one time, which has the advantage of lasting and non-fading. In addition, it is excellent in weather resistance and is particularly suitable as a decoration for an exterior wall of a building.

Read more