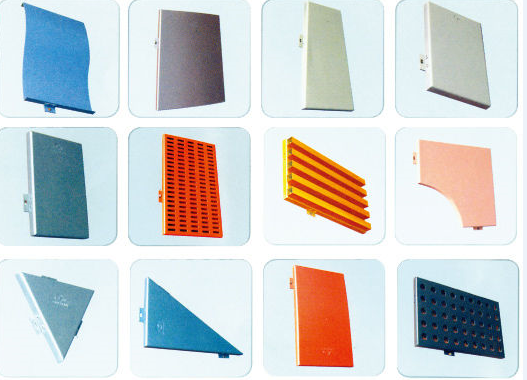

China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum honeycomb panels have many characteristics that conventional materials do not have, mainly in the following aspects

Read more

Aluminum honeycomb panel is a kind of composite material developed by high toughness adhesive. It has the characteristics of light weight, high impact resistance, high rigidity, high flatness, many surface colors and flexible design.

Read more

At present, as the requirements of the acoustic performance of the occasion, such as hall, hall, hall, field decorative sound-absorbing panels, aluminum honeycomb panels and other sound-absorbing materials such as sound-absorbing paper, glass fiber cotton and other functional combination, play their respective advantages, can play a better sound-absorbing effect.

Read more

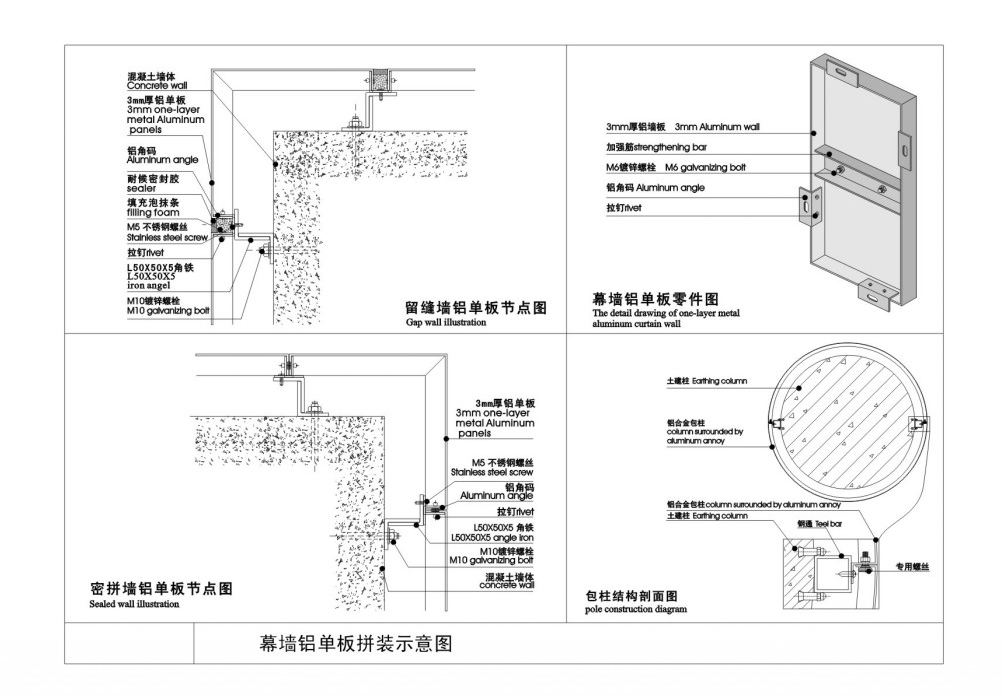

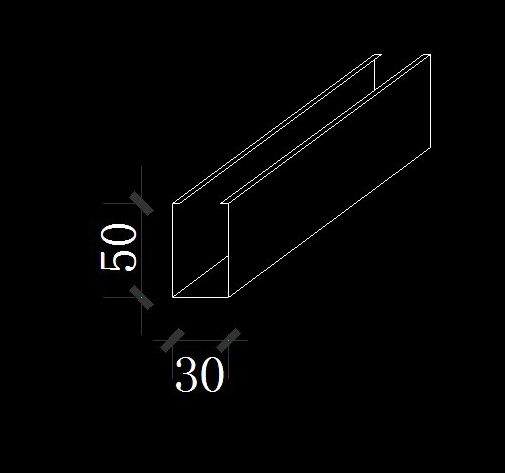

Material and structure of aluminum veneer curtain wall: aluminum veneer curtain wall is made of high-quality and high-strength aluminum alloy plate, and its common thickness is 1.5mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm, model 3003, state H24. The maximum size of conventional materials is 1220MM x 2440MM. Its structure is mainly composed of panels, stiffeners and corner codes. The corner code can be directly bent and stamped from the panel, or riveted on the small edge of the panel. The reinforcement is connected with the electric welding screws behind the plate surface, making it a solid whole, greatly enhancing the strength and rigidity of the aluminum veneer curtain wall, and ensuring the flatness and wind resistance and earthquake resistance in long-term use. If sound insulation is required, high-efficiency sound insulation materials can be installed on the inside of the aluminum plate. Surface treatment of aluminum veneer curtain wall The surface of aluminum veneer curtain wall is

Read more

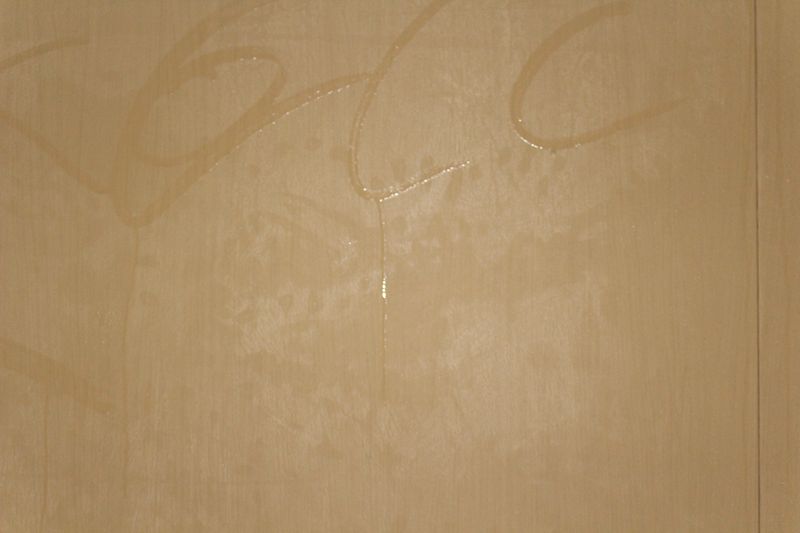

1. material requirements: 1. Material: The material selection of aluminum veneer shall conform to the provisions of GB/T5237 Aluminum Alloy Building Profiles, and the commonly used material type is 3003H24; The thickness of aluminum veneer to be used in this project is 3mm. 2, coating: fluorocarbon paint coating, coating times shall not be less than two, the thickness should be greater than 25μm; and fluorocarbon resin content should not be less than 75%; fluorocarbon coating should be free of blisters, cracks, peeling and other phenomena. 3. Processing, storage and handling: The stiffening ribs and connecting parts of aluminum veneer can be welded and riveted, and the positions should be accurate and firm. The surface layer of aluminum veneer shall be pasted with a polyethylene plastic protective film with a thickness of not less than 0.3mm, and the inner and outer surfaces of aluminum veneer shall not be scratched. 4. Allowable deviation of aluminum veneer processing size: unit (mm) 2. main machines and tools: 1. Tools: electric welding machine, cutting saw, electric hand drill, riveting gun, barrel glue injection gun, portable air pressure cleaning machine, pulley, brown rope, nylon rope, screwdriver, tool knife, plaster knife, etc. 2. Measurement, setting-out and inspection: level, theodolite, total station, steel tape, level ruler, steel wire, etc. Main construction process of 3.

Read more

Aluminum honeycomb plate glue, also known as polyurethane glue, is used for the bonding of color steel plate, aluminum plate and aluminum honeycomb. It is one of the essential raw materials for the production of manual purification board and exterior wall insulation and decoration materials.

Read more