China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum honeycomb panel curtain wall has been dominant in the metal curtain wall, lightweight material, reduce the load of the building, for high-rise buildings to provide a good choice of conditions; waterproof, anti-fouling, anti-corrosion performance is excellent.

Read more

In fact, most consumers can not distinguish the characteristics of curtain wall aluminum veneer and aluminum honeycomb panel curtain wall. So we in order to help you buy the right building materials, the following to introduce their characteristics.

Read more

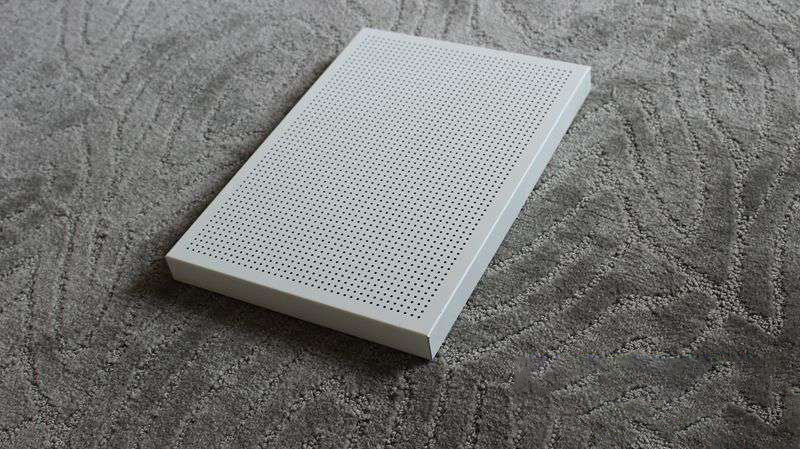

Aluminum honeycomb panel is a series of metal composite panel Products developed in combination with the aviation industry composite honeycomb panel technology. The product uses a honeycomb sandwich structure, that is, a high-strength alloy aluminum plate with a decorative coating with excellent weather resistance is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

Read more

Maintenance, Use and Maintenance Manual for Aluminum Corrugated Board Article 1 In order to ensure that Chinalco corrugated board reaches its design service life under normal use and maintenance, the operation and maintenance manual for corrugated aluminum board is specially formulated. Article 2 According to the GB50068 of the Unified Standard for the Reliability Design of Building Structures, corrugated aluminum plates are easy-to-replace structural parts, and the design service life of corrugated aluminum plates belongs to the second category, and its design service life is 25 years. 1, the project basic wind pressure take WO = 0.45 KN/m2; 2, the project corrugated aluminum plate seismic according to 6 degrees to prevent; 3, the project corrugated aluminum plate rod, using galvanized channel steel and galvanized angle steel; 4, the project corrugated aluminum plate pure aluminum plate, mining

Read more

In the selection of aluminum corrugated board manufacturers that meet the requirements of environmental protection, its specifications are still relatively large. In the selection of plates, aluminum plates with relatively high hardness can be selected. In the purchase, many comparisons should be made, and the aluminum plate model specifications should be selected according to the design drawings.

Read more

Why are the prices of aluminum honeycomb panels on the market different? Many customers will encounter different prices when consulting and purchasing aluminum honeycomb panels, some with a difference of 10 pieces, some with a difference of 50 pieces and some even more. So today and everyone to talk about the price of aluminum honeycomb panel in the end where the difference. 1. Raw materials: Basically, the raw materials are supplied at the same price. This is because some small manufacturers sell the 1 series as the 3 series in order to fight a price war, or buy some inferior aluminum as good aluminum. If the appearance is not visible, it must be tested. This will save more than ten dollars. 2. Glue: aluminum honeycomb panels generally use polyurethane glue and polymer film, but these two kinds of glue are also good and bad, with a difference of dozens of pieces. You all understand. Another is the amount of glue applied, and less is also money. Now the basic conventional specifications will use automatic glue spraying machine. 3. Composite process: Some people finish the process in a few procedures, so the most direct problem will lead to poor quality of the board, or poor weather resistance, short service time, normal aluminum honeycomb panels have 14 procedures, so

Read more