China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

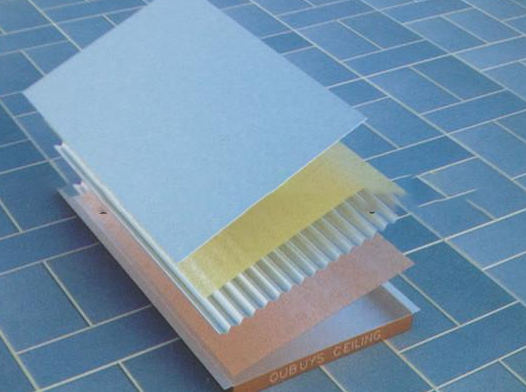

Aluminum corrugated board manufacturersThe single block has a large area, the maximum single block can be 3m × 1.5m, strong plasticity, excellent manufacturing technology, characteristic appearance and feeling of surface metal texture, very modern feeling, and many color varieties, so it can better reflect the design idea.

aluminum corrugated boardThe installation process and method of the aluminum-plastic plate are consistent with the installation and construction process of the aluminum-plastic plate, so the installation process and technology are easier. The aluminum veneer needs to be transported to the site after processing in the factory, and it needs to be processed and delivered from the factory in case of breakage. Corrugated composite aluminum plate can transport the plate and processing machines to the site for on-site processing, which has obvious advantages for buildings with complex shapes.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Aluminum corrugated board, also known as corrugated aluminum plate, profiled aluminum plate, aluminum tile, etc., is a profiled board that uses aluminum plates to be rolled and bent into various waveforms. It is suitable for industrial and civil buildings, warehouses, special buildings, roofs, walls, and interior and exterior wall decorations of large-span steel structure houses. It has the characteristics of light weight, high strength, rich color, convenient and fast construction, earthquake resistance, fireproof, rainproof, rainproof, rainproof, long life, long life, maintenance-free, etc, has been widely used.

aluminum corrugated boardThe quality of the manufacturer\'s panel is the key to the whole processing process. When the ductility of the panel aluminum material is not high and the thickness is too thin, the panel is easy to break when the curved surface is bent. Therefore, the panel should not be aluminum plate with a thickness of less than 0.8mm, and the material should be the national standard 3003H24 aluminum alloy coil.

The weight of the aluminum corrugated board is light, and its weight per square is only equivalent to 50% of the aluminum veneer.

Aluminum corrugated board manufacturers have strong rigidity: due to the large corrugated height and good cushioning, this is because of its large section size and the corresponding increase in edge compressive strength. The number of corrugated, more support points in the plane, the formation of a small structure, flat compression strength will be improved accordingly.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Composite aluminum-plastic plate has the same plasticity as aluminum veneer. Its advantages are light weight, good surface smoothness, no color difference when installed in the same direction, and excellent on-site processability. It creates conditions for the change of exterior wall size caused by construction errors and for reducing the processing cycle and shortening the installation period.

Recommended:What are the specifications of corrugated aluminum plate