China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

1, becausealuminum honeycomb panelWith the continuous support of the sandwich core on the surface, the panel can fully exert its ability to withstand tensile or compressive loads.

2、Aluminum honeycomb panel processThe interlayer has good sound insulation and heat insulation effect. In the aluminum honeycomb core of the commonly used honeycomb sandwich panel, the volume of the solid material is only 1% ~ 3%, and the remaining space Inside is air in a closed state. Because the sound insulation and heat insulation performance of air is better than that of any solid material, the heat energy and sound wave are greatly limited, so the honeycomb sandwich panel has good heat insulation and sound insulation performance.

3, for the main bending of the structural parts, select the appropriate plate and sandwich material, can achieve the best stiffness-weight ratio.

4. The interlayer of the aluminum honeycomb panel process has many dense honeycombs that contain each other, just like many small I-beams that can be dispersed to bear the pressure from all parties. Therefore, it has a strong seismic capacity.

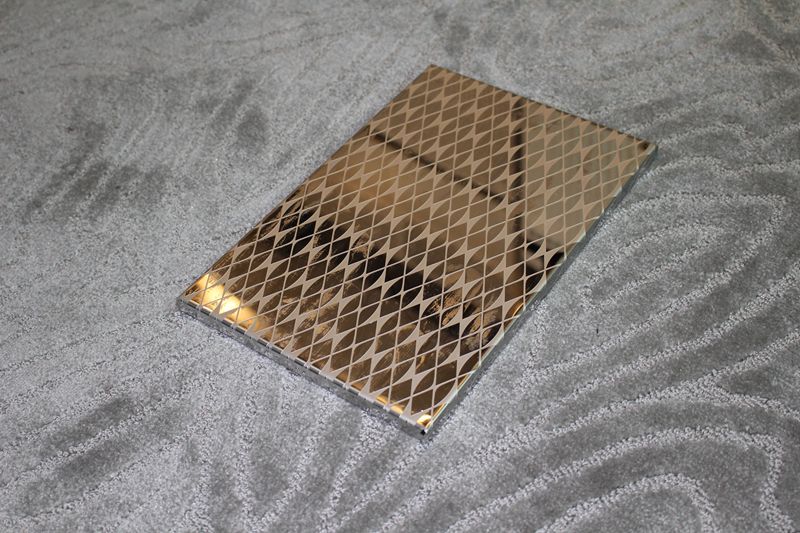

Aluminum honeycomb panels are popular building materials for consumers. Its production process requirements are high, not only the application of advanced technology and technology, but also to ensure its strength, gloss, flatness, while ensuring its corrosion resistance, but also insulation.

The design idea of aluminum honeycomb panel structure comes from I-beam structure: the surface plate is equivalent to the wing plate of I-beam and mainly bears normal stress; The middle honeycomb layer is equivalent to the web plate of I-beam and mainly bears shear stress. The structure of the two panels of the aluminum honeycomb panel process is high and has a large sectional moment of inertia, so it has good rigidity and high bending strength. The middle sandwich layer is bionic in the natural honeycomb structure, with less materials, but with high shear strength and good stability. The optimal combination of the panel and the honeycomb intermediate layer makes the honeycomb panel have the advantages of light weight, high strength and good rigidity.