China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

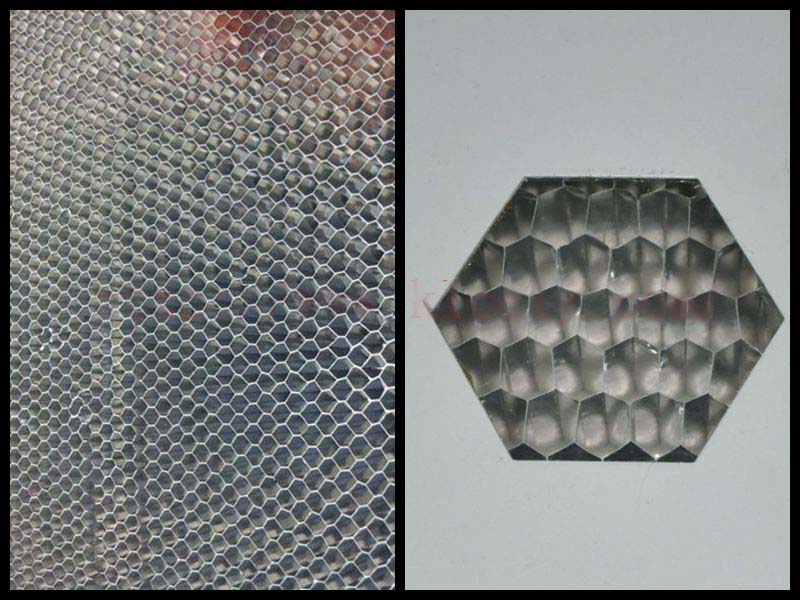

Aluminum Honeycomb SheetSuitable for civil construction, vehicle and ship decoration, etc. It is the application of aviation and aerospace materials in the field of civil construction. The whole processing process is completed in a modern factory. Hot pressing technology is adopted. Due to the high thermal conductivity value between the aluminum skin and the honeycomb, the thermal expansion and cold contraction of the inner and outer aluminum skin are synchronized. There are small holes in the honeycomb aluminum skin, so that the gas in the plate can flow freely. The slidable installation buckle system will not cause structural deformation during thermal expansion and contraction.

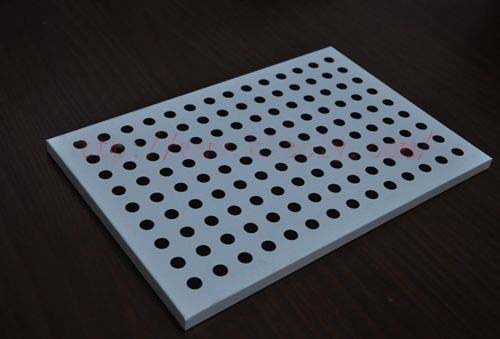

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Aluminum honeycomb sheet has high wind pressure resistance, shock absorption, sound insulation, heat preservation, flame retardant and high specific strength. In the 1960 s, foreign countries have been used in various fields of civil use, and have developed rapidly. In recent years, cellular technology has been applied in various fields of civil industry. Aluminum honeycomb panel curtain wall with its light weight, high strength, stiffness and many other advantages, has been widely used in high-rise building exterior decoration.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Aluminum honeycomb sheet is one of the types of aluminum, it refers to the use of plastic processing method of aluminum ingot after rolling, extrusion, stretching and forging and other methods of final manufacturing into plate aluminum Products, in order to ensure the final performance of the plate and then the finished product annealing, solid solution treatment, quenching, natural aging and artificial aging treatment.

Aluminum honeycomb plates are commonly used in signboards, billboards, building exterior decoration, bus bodies, wall decoration of high-rise buildings and factories, kitchen sinks, lamp holders, fan blades, electronic parts, chemical instruments, sheet metal processing parts, deep-drawing or spinning concave vessels, welding parts, heat exchangers, clock surfaces and disk surfaces, nameplates, kitchen utensils, decorations, reflective appliances, etc.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Honeycomb aluminum plate is a series of metal composite panel Products developed in combination with the aviation industry composite honeycomb panel technology. The honeycomb aluminum plate adopts the honeycomb sandwich structure, that is, the high-strength alloy aluminum plate with excellent weather resistance and decorative coating on the surface is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

Recommended:The working principle of aluminum honeycomb panel equipment