China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

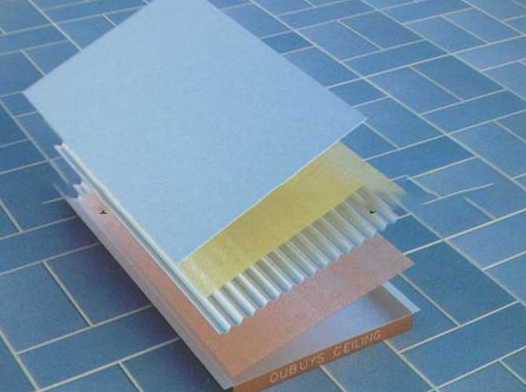

Hook up corrugated boardUsing aluminum alloy plate as the panel, aluminum corrugated core as the core material, according to the application environment and material requirements of the plate to choose the back plate (not composite back plate), the use of composite aluminum plate production technology to manufacture an aluminum composite plate. It has the characteristics of more than wide board surface, good flatness and small size of falling deviation.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

The core board that hooks up the corrugated board is a water corrugated type, and an air channel is formed between the panel and the back plate. It is a hollow board system and is the best product for heat insulation. Under the action of solar radiation, the air in the channel heats up and flows upward to take away heat, which has heat insulation performance.

In cold areas, the upper and lower ends of the corrugated channel are sealed. During the day, under the sunlight, the heat energy is stored to reduce the loss of indoor heating heat, and it has heat preservation performance. The waste material in the project can be recycled by 100, which is environmentally friendly and pollution-free.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Hook up corrugated board color range, bright and beautiful, good texture. The surface can be sprayed into a variety of colors, can also be made of wood grain and stone hook corrugated board, reflecting the simple modern decorative style.

The flatness of the outer surface of the honeycomb panel is better, but the price is higher and should not be adopted by the project. The tensile, compressive strength and 180-degree peel strength of aluminum corrugated board (see the test report for details) are higher than those of honeycomb board, so it has ultra-high surface flatness, stability and durability, and the same life as the building.

Hook up corrugated board product uses: building exterior walls, beams, balconies, waiting rooms. Waiting room, conference hall, opera house, stadium, reception hall and so on.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Hook up corrugated board is the use of aluminum plate after rolling cold bending into a variety of waveform pressure plate, it is suitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure housing roof, wall and interior and exterior wall decoration.

It has the characteristics of light weight, high strength, rich color, convenient and quick construction, earthquake resistance, fire prevention, rain prevention, long life, maintenance free, etc., and has been widely promoted and applied.

Recommended:Applicable scope of stainless steel honeycomb density board