China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Honeycomb aluminum plateThe installation shall be in place according to the plate number on the plate distribution drawing, the installation angle code of the gelatin seam part shall be assembled, and check whether the angle code of the adjacent two plates is staggered, and check the levelness and verticality of the trial assembly, then assemble with stainless steel bolts, try to fix it on the main and auxiliary keels, adjust the horizontal and vertical seam clearance to meet the requirements, and then fix it.

In the hidden joint position, the hidden joint pressure plate is used to fix, check the two gaps to ensure consistency, the specific requirements should ensure that the honeycomb aluminum plate left and right, up and down deviation of ± 1.5mm, pay attention to the hidden joint pressure plate should be sealed with sealant, glue seam should be greater than 5mm and should ensure its tightness.

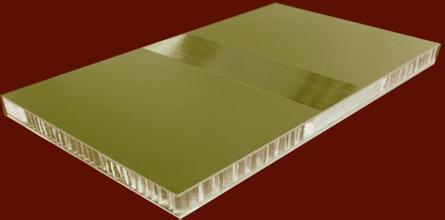

Honeycomb aluminum plate shall be installed on both sides without mechanical damage. The sliding installation buckle system allows thermal expansion and contraction, and the anti-slip buckle at the bottom of the board can control the expansion direction of the board. 25MM hidden glue joint system is beautiful and has self-cleaning function. After the completion of the production of the box-type honeycomb plate, the inner and outer plates and the honeycomb structure form a whole. In addition, the hollow honeycomb can also greatly reduce the thermal expansion of the plate body.

Because the honeycomb material has high wind pressure resistance, shock absorption, sound insulation, heat preservation, flame retardant and high specific strength. In the 1960 s, foreign countries have been used in various fields of civil use, and have developed rapidly. In recent years, cellular technology has been applied in various fields of civil industry.

Honeycomb aluminum curtain wall has been widely used in high-rise building exterior wall decoration because of its light weight, high strength, high stiffness and many other advantages. The aluminum honeycomb panel with a total thickness of 15mm and a panel floor of 1.0mm is only 6Khg/㎡. The weight of honeycomb panel with the same rigidity is only 1/5 of that of aluminum veneer and 1/10 of that of steel plate. The interconnected aluminum honeycomb cores are like countless I-beams of aluminum curtain wall. The core layers are distributed and fixed in the whole plate surface to make the plate more stable. Its wind pressure resistance is much higher than that of aluminum new plate and aluminum veneer. Aluminum curtain wall has the characteristics of not easy deformation and good flatness, even if the cell size of honeycomb aluminum plate is large.