China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

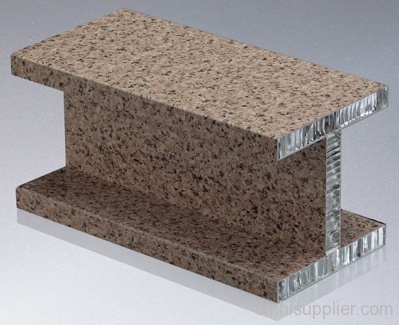

Aluminum honeycomb panel? is a kind of low density and high strength material made by bionic principle, which is made of aluminum honeycomb core and panel by adhesive bonding. Aluminum honeycomb panel is a kind of lightweight high-strength multi-purpose sandwich material, its specific rigidity and strength, the same thickness of the aluminum honeycomb panel than the rigidity is 5 times that of the aluminum plate, 10 times that of the steel plate.

Read more

1. Effect of Adhesive on Peel Strength of Aluminum Honeycomb Panel (1) The adhesive strength of aluminum honeycomb panel produced by polyurethane and epoxy resin room temperature curing adhesive is low. The 180 peel strength measured for aluminum honeycomb panel with honeycomb core side length of 4mm, panel thickness of 1mm and total thickness of 10mm is about 4N/mm. The adhesion and weather resistance of this aluminum honeycomb panel are poor, and the adhesion performance is greatly reduced after 1 year of use. The aluminum honeycomb panels produced by this process are not suitable for outdoor use, but can be used for indoor decorative partitions. (2) The adhesive strength of aluminum honeycomb panel produced by epoxy film process is low. The 180 peel strength measured for aluminum honeycomb panel with honeycomb core edge length of 4mm, panel thickness of 1mm and total thickness of 10mm is about 4N/mm. However, its adhesive performance is good in weather resistance, and its peel stre

Read more

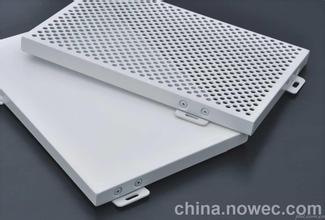

A low density and high strength material made by bionic principle. Honeycomb sandwich panel made of aluminum honeycomb core and panel by adhesive bonding is a kind of lightweight and high-strength multi-purpose material. Its specific rigidity and specific strength are large. The specific rigidity of aluminum honeycomb panel of the same thickness is 5 times that of aluminum plate and 10 times that of steel plate. Due to the characteristics of honeycomb sandwich panels, it was first applied to aerospace vehicles. It greatly reduces the weight of aerospace vehicles while ensuring its function, and can travel longer distances using the same fuel. With the continuous progress of manufacturing technology and the development of materials, honeycomb sandwich panels are widely used by more and more other industries, such as shipbuilding, ground transportation, machinery, architectural decoration and other industries. The following will briefly introduce the main performance of aluminum honeycomb panels: (1) decorative performance The surface coating of aluminum honeycomb panel is fluorocarbon baking varnish, polyester powder spraying, acrylic baking varnish, fluorocarbon or polyester roller coating decoration. Since the aluminum honeycomb panel is equivalent to countless I-beam structures, it is endowed with greater rigidity and bending strength and small bending deformation. Honeycomb plate surface flatness is high, which is much better than single aluminum plate and aluminum-plastic plate, and can produce larger size plate surface (1.5m × 1

Read more

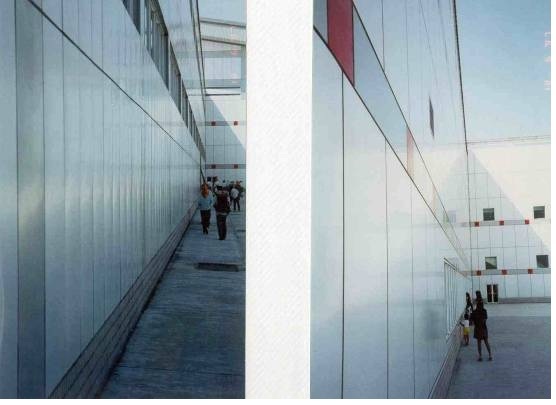

Stainless steel aluminum honeycomb panel? project will be in service for many years. This durability means playing a major role in the development of a more sustainable society: improving energy efficiency, reducing pollution, and reducing the use of materials.

Read more

Aluminum honeycomb panel is a kind of low density and high strength material made by bionic principle. The honeycomb sandwich panel made of aluminum honeycomb core and panel bonded by adhesive is a kind of lightweight and high-strength multi-purpose material with high rigidity and strength. Due to the characteristics of honeycomb sandwich panels, it was first applied to aerospace vehicles. It greatly reduces the weight of aerospace vehicles while ensuring its function, and can travel longer distances using the same fuel.

Read more

When it comes to aluminum honeycomb, I don't think people in the industry will know that the origin of aluminum honeycomb panels comes from aluminum veneer. Scientists have found that the nest made by bees is a hexagonal six-sided object, which is stronger than any other shape. This multi-wall arrangement structure and network structure can disperse the external force from all parties, making the honeycomb structure resistant to extrusion force, much higher than any round or square structure. Honeycomb structure to people's inspiration: even if the use of very thin materials, as long as it is made into a honeycomb shape, it can withstand strong pressure, it is this revelation, aluminum honeycomb plate material began to appear. At first, aluminum veneer was used for decoration. Later, it was found that aluminum honeycomb panels would be more decorative and functional than aluminum veneer, and this emerging industry officially grew up. But the market of aluminum honeycomb panel is reall

Read more