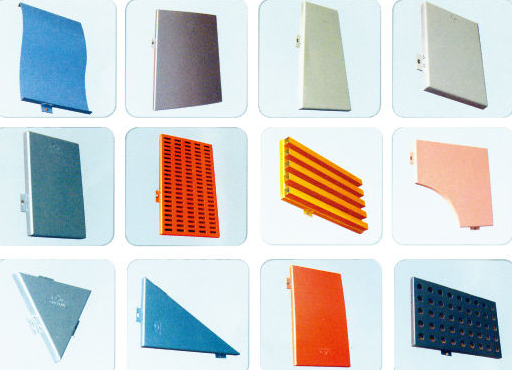

China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

The aluminum alloy plate of aluminum honeycomb panel is a kind of cost-effective building material, which has the advantages of corrosion resistance, beautiful appearance, light weight, high strength, easy processing and so on.

Read more

The connection method of honeycomb core and panel of honeycomb aluminum plate also has 2 kinds of bonding and welding. The gluing method is to heat and pressurize the panel and core with hot curing glue in a continuous forming machine and then compound them.

Read more

The aluminum honeycomb panel adopts the honeycomb sandwich structure. The aluminum honeycomb panel is composed of the front and back aluminum alloy plates and the middle aluminum honeycomb. During installation, each plate is wrapped around to form a closed box structure.

Read more

Aluminum honeycomb panel specifications are determined by the thickness of aluminum foil and honeycomb cell size. Different specifications of aluminum honeycomb have different densities and different mechanical properties, and their cost also varies greatly.

Read more

The panels on both sides of the aluminum honeycomb panel are high-strength aluminum plates, and the inner layer is a special hexagonal aluminum honeycomb, which is used as a core plate adhered to the sandwich structure and bears pressure in the tangential direction

Read more

The box-type honeycomb aluminum plate adopts a buckle cover system, which can be selected from two systems: exposed glue seam and hidden glue seam. The system fully considers the influence of thermal expansion and cold contraction on the plate surface itself, and the four directions of the plate surface can be freely expanded and contracted, effectively avoiding the influence of temperature stress on the flatness of the plate surface.

Read more