China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

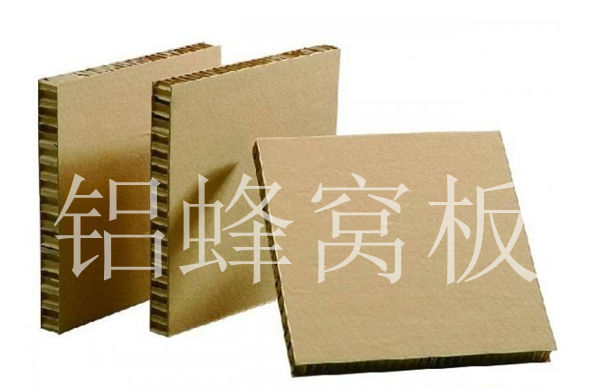

Aluminum honeycomb panel is a kind of high-grade building decoration material for exterior walls. In the past, it was only used in the aerospace industry with high requirements. It is the application of aviation and aerospace materials in the field of civil construction. It is the best product in the current metal curtain wall building materials. Let Xiaobian tell you what are the advantages of aluminum honeycomb panel.

Read more

Because of its green environmental protection and low price, it is increasingly valued and supported by the relevant departments of the state, and is widely used in more and more fields, and the market is constantly expanding. With the breakthrough of technology, China\'s honeycomb structure composite materials have broken the technological monopoly of the United States, Canada, the European Union and other countries and regions. Due to its good performance, the application involves architectural decoration, furniture, electrical appliances, energy, railways, automobiles, ships, aerospace and many other fields, the market is broad and full of opportunities. 1. Industry Overview Honeycomb structures are a special type of composite material. Because this light structural material has the characteristics of optimal specific strength, specific stiffness, maximum fatigue resistance and smooth surface, it has been widely used in China\'s aerospace field. The honeycomb structure is essentially a composite material composed of 3 basic materials, which provides the possibility to change the parameters to meet the design specifications. At present, the most commonly used in model tasks are aluminum panel-aluminum honeycomb sandwich structure, carbon fiber panel-aluminum honeycomb sandwich structure, glass fiber reinforced plastic panel-glass fiber reinforced plastic honeycomb sandwich structure, etc., which are characterized by complex structure, high dimensional accuracy requirements, and many process contents.

Read more

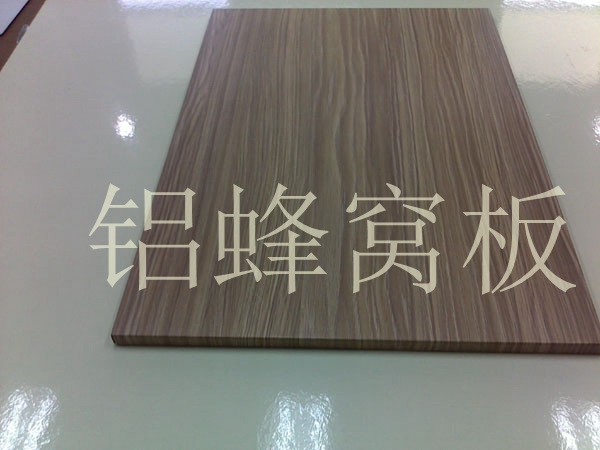

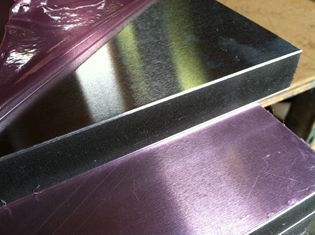

Aluminum honeycomb panel is a high-grade aluminum alloy panel, back plate and aluminum honeycomb core material hot pressing composite molding of large surface composite materials, product specifications are diverse, the surface can be embossed, mirror, relief, drawing, electroplating, anodizing, matte, bright light and metal color and other treatments, to meet the application needs of a variety of places. Surface treatment technology through some physical and chemical means to give the surface of the material with special properties to meet the various requirements of the material, all these changes in the physical and chemical properties of the material surface processing technology is collectively referred to as surface treatment or surface processing. With the continuous development of surface treatment technology, the surface of some base materials has some characteristics that are not available, which greatly expands the application range of materials and gives full play to the p

Read more

The aluminum honeycomb panel produced by polyurethane and epoxy resin room temperature curing adhesive has low bonding strength. The 180 peel strength measured for aluminum honeycomb panel with honeycomb core side length of 4mm, panel thickness of 1mm and total thickness of 10mm is about 4N/mm.

Read moreAluminum honeycomb panel presents honeycomb, better sound insulation, sound absorption, thermal insulation is strong, is the current exterior wall construction, interior decoration of the most factory use of building templates. There are often four factors that directly affect the quality of aluminum honeycomb panels, the following small series for everyone to introduce in detail.

Read more

In recent years, honeycomb aluminum plate has been widely used in all walks of life, and it has a wide variety of superior characteristics. Honeycomb aluminum plate is a new type of composite material with sandwich structure, which is composed of upper and lower aluminum sheets and aluminum honeycomb core through adhesive.

Read more