China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

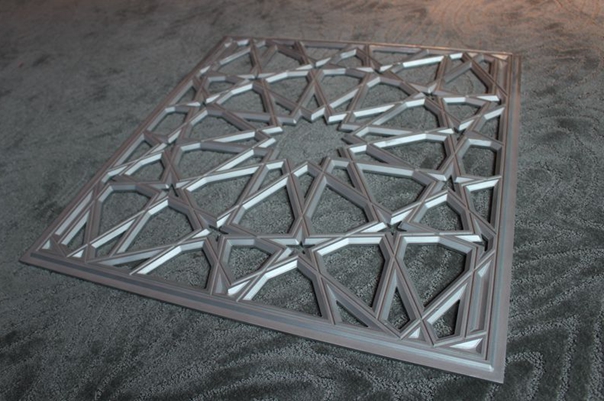

Nowadays, with the rapid development of the national economy and the continuous improvement of people\'s living standards, people are paying more and more attention to visual enjoyment, and carved aluminum plate has its unique advantages in decoration and environmental protection performance, so it has been unanimously recognized by people. However, with more and more Products on the market, consumers are at a loss when choosing, so what aspects need to be considered when choosing carved aluminum plate?

What to consider when choosing carved aluminum plate?

1. The impact of the production process.

When selecting materials, the manufacturability of carved aluminum plate should be considered. The surface finish and paint uniformity provided by the manufacturer can be selected. The better the surface finish and paint uniformity, the finer the process.

2. Product price.

Therefore, when consumers choose carved aluminum plate, they can choose by comparing the quality and price of multiple Products, so as to choose a more cost-effective and more affordable carved aluminum plate product.

3. The decorative style of the building and its corrosion resistance.

Carved aluminum plate has good corrosion resistance and long service life. Therefore, consumers should carefully consider its corrosion resistance effect when choosing carved aluminum plate, so as to ensure that the selected Products will have better use effect. In addition, the architectural style and the application site should be considered to choose the most satisfactory carved aluminum leather Products.

Carved aluminum plate is a kind of commonly used building materials, its application range is very wide, then the processing process of carved aluminum plate we understand.

Carved aluminum plate three main process requirements:

1. process requirements

Equipped with cutting, punching, bending, arc-shaped plate rolling machine, can complete a variety of basic sizes and shapes of carved aluminum processing; aluminum argon arc welding, high-frequency welding nail equipment, to ensure that the aluminum plate forming welding. Angle, and high texture to complete the stiffener nailing process; mechanized grinding and polishing equipment with automatic pretreatment tank, and a unique spray booth and oven. Can complete the processing of large plates and long profiles, so that the surface of the product to meet the requirements of the coating substrate film.

2. spraying process requirements

Chemical pretreatment is to remove organic and inorganic stains on the metal surface by chemical methods, then remove the natural oxide layer, and then use chemicals to generate an oxide film, so that the metal surface forms an anti-rust agent and can adhere for a long time. Electrostatic coating adopts advanced automatic electrostatic spray paint, and the fluorocarbon paint is sprayed layer by layer on the metal base surface of the carved aluminum plate according to the process requirements, and is baked and cured according to a certain temperature and time.

3. Quality Assurance System Requirements

用高精度的检验和包装检测仪器,对产品质量进行严格检验.确保carved aluminum plate尺寸精度达到企业标准,漆膜质量符合标准。铝塑板与铝单板的施工工艺大致相同,最大的区别就是carved aluminum plateIn the field processing into the required shape and specifications, there is a great degree of freedom of construction, and the aluminum plate is processed by the manufacturer. In addition, the construction process guarantees the delivery time, the mass production of carved aluminum plates is much faster than the production of aluminum-plastic plates, and the construction schedule guarantee system has also been improved.