China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Bee aluminum plate is a new type of decorative material, which is composed of aluminum panel, aluminum honeycomb core and aluminum back plate. Corrugated aluminum plate is composed of aluminum plate, aluminum corrugated core and aluminum back plate. Corrugated aluminum plate is widely used in industrial and civil buildings, punching, large span steel structure housing roof, wall and interior and exterior wall decoration, this small series introduces the specific characteristics of corrugated aluminum plate.

1, light weight, high strength: corrugated aluminum plate is made of high quality aluminum, the density is only steel 1/3, light weight, good strength;

2, good weather resistance: corrugated aluminum plate corrosion resistance, waterproof, moisture-proof, maintenance-free, long service life;

3. Easy installation: Corrugated aluminum plate is easy to process, convenient and quick construction, which greatly reduces the construction intensity;

4, decorative: the color and shape of corrugated aluminum plate has a variety of choices, beautiful appearance, aluminum bright, aluminum bright, resistant to fading;

5, high recovery value: corrugated aluminum plate due to its corrosion resistance, recycling furnace value is higher, recycling is larger.

How to determine the quality of corrugated aluminum?

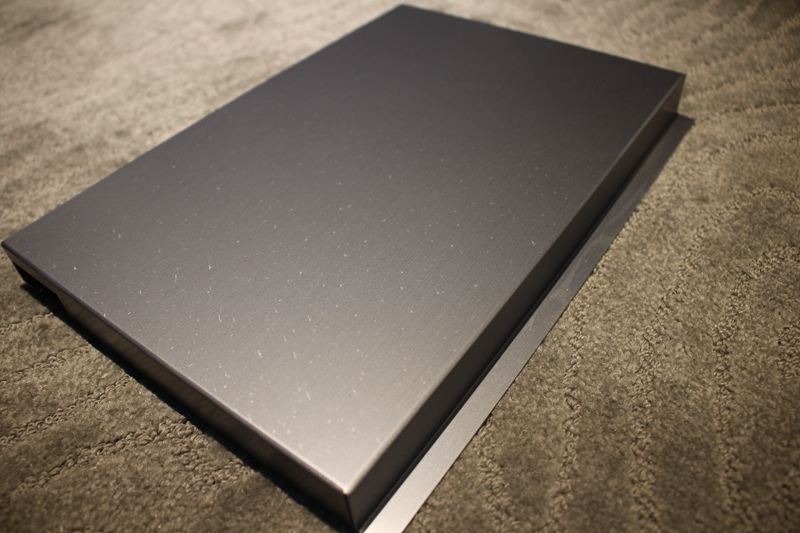

1, check the corrugated aluminum surface, whether there are particularly serious scratches. Aluminum tiles belong to mechanical processing, there will inevitably be some scratches, too much scratches will affect the appearance. If the aluminum tile surface requirements are high, the manufacturer can be required to film processing in advance.

2. Check the flatness of the aluminum corrugated board, and use the aluminum tile processed by the base material and equipment, with a smooth appearance and no ruffles or ripples. There will also be no bending and sagging after installation.

3. Check the coating of aluminum corrugations. Color aluminum tile coatings are generally divided into polyester coatings and fluorocarbon coatings, good coating surface clean, smooth, no water. The shelf life of polyester coatings is 5-8 years without fading, and the warranty period of fluorocarbon coatings is 15-20 years.