1. product introduction:

Kaimai metal building materials corrugated composite board uses alloy aluminum plate as the panel, aluminum corrugated core as the core material, according to the application environment of the plate and material requirements to choose the back plate (not composite back plate), the use of composite aluminum plate production technology to manufacture an aluminum composite board. It has the characteristics of more than wide board surface, good flatness and small size of falling deviation.

Corrugated aluminum sheet specification parameters

2. product specifications:

总厚度:面板厚度+瓦楞芯厚度(3mm-15mm)+底板厚度;

The thickness of the aluminum skin used is generally 0.2 mm-0.6mm.

Width: 600mm, 900mm, 1200mm mm, the maximum size does not exceed 2200mm;

Length: arbitrary mm

corrugated aluminum plate

3. product features:

1. The bonding performance is stable, firm and durable:

The aluminum corrugated board is made of AL3003H16-H18 material, the thickness of the panel is 0.7mm ~ 1.0mm, the thickness of the back plate is 0.5 - 1mm (the same as that of the aluminum honeycomb board), the core board is made of AL3003H16-H18, the thickness of the material is 0.2mm, 0.25mm,0.3mm, it is water corrugated type, and the bonding surface with the back plate is arc type, which increases the bonding strength. The thermosetting resin adhesive has excellent bonding force of the metal plate, production on advanced fully automated production equipment to ensure that the bonding performance is stable and durable with the construction of the same life.

2. Energy saving and environmental protection:

The core board of aluminum corrugated board is water corrugated type, which forms an air channel between the panel and the back plate. It is a hollow board system and is the best product for heat insulation. Under the action of solar radiation, the air in the channel heats up and flows upward to take away heat, which has heat insulation performance. In cold areas, the upper and lower ends of the corrugated channel are sealed. During the day, under the sunlight, the heat energy is stored to reduce the loss of indoor heating heat, and it has heat preservation performance. The waste material in the project can be recycled by 100, which is environmentally friendly and pollution-free.

3. Sound insulation and noise reduction:

Because the core board is a corrugated arc type, it produces a curved surface reflection of the sound wave, eliminates the sound wave coupling between the panel and the back plate, and improves the sound insulation performance by more than 35dB.

4. Super high flatness:

Because the thickness of aluminum panel is 0.7-1.0mm, the carrying capacity of aluminum corrugated board is small after folding, so it is not suitable for large plate or large height curtain wall project. Due to the linear expansion coefficient of 2.35x 10-5, the aluminum veneer has a large deformation due to cold shrinkage and thermal expansion. Generally, the surface of the aluminum plate will have concave-convex deformation after 1-2 years of use, which will affect the artistry of the building facade. The flatness of the outer surface of the honeycomb panel is better, but the price is higher and should not be adopted by the project. The tensile, compressive strength and 180-degree peel strength of aluminum corrugated board (see the test report for details) are higher than those of honeycomb board, so it has ultra-high surface flatness, stability and durability, and the same life as the building.

5, light weight, economical:

When the aluminum corrugated board is 6mm thick, the specific gravity is 4.3kg/㎡. Because the heavy load of the surface material is small, the structural supporting keel can be reduced, which is more economical.

6. Easy to clean, corrosion resistance, strong anti-fouling ability, durability and no discoloration.

7. Easy processing and installation:

Easy processing: cutting, punching, bending, can be made into special-shaped flat plate, arc plate. Side ribs and reinforcing aids can be connected by pulling rivets, which is simple and firm.

Easy installation and construction: fixed distance crimping, hanging, opening and closing structure can be used to ensure smooth surface, safety and durability, and more architectural art.

corrugated aluminum plate

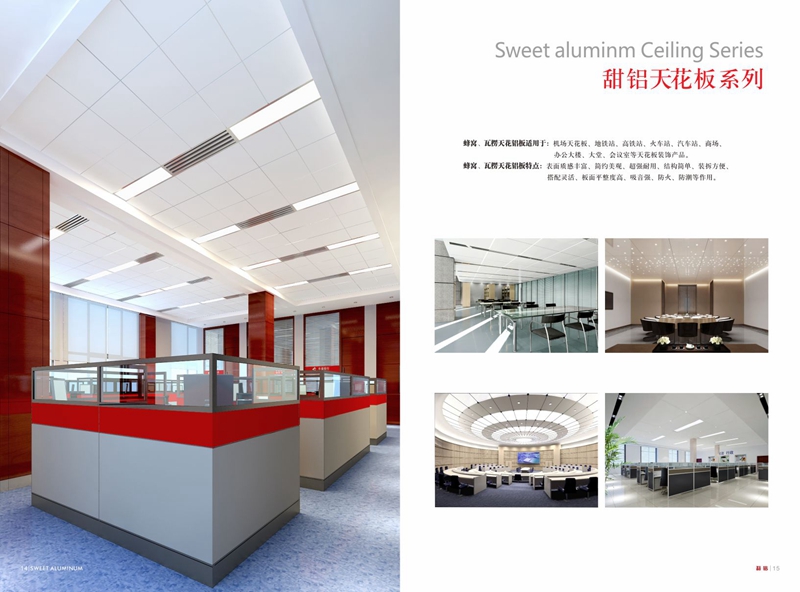

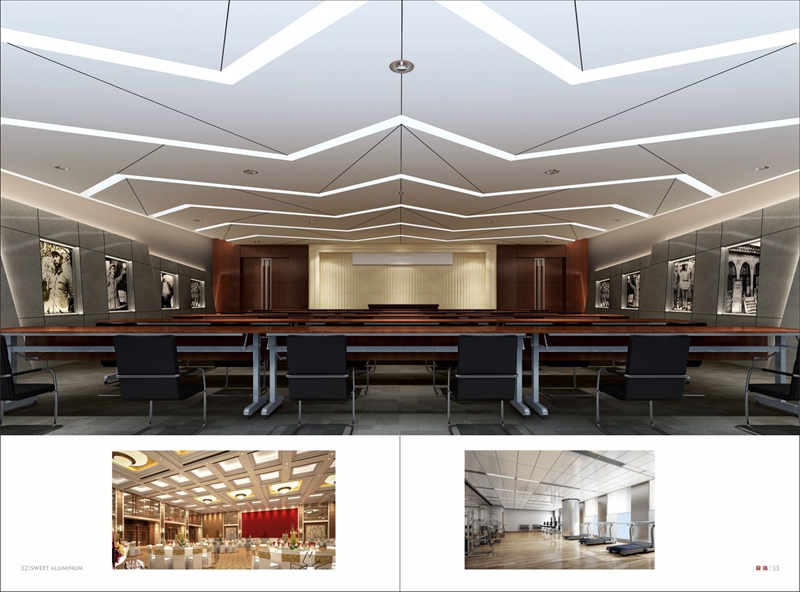

4. product use:

Building exterior wall, beam column, balcony, waiting room. Waiting room, conference hall, opera house, stadium, reception hall and so on.

corrugated aluminum plate

Corrugated aluminum curtain wall is made of high-quality and high-strength aluminum alloy plate, and its common thickness is more than 2.5mm and 3.0mm, and its state is H24. The maximum size of conventional materials is 1220MM x 2440MM. Its structure is mainly composed of panels, stiffeners and corner codes. The corner code can be directly bent and stamped from the panel, or riveted on the small edge of the panel. Strengthening

The reinforcement is connected with the electric welding screw behind the plate surface, making it a solid whole, greatly enhancing the strength and rigidity of the aluminum veneer curtain wall, and ensuring the flatness and wind resistance and earthquake resistance in long-term use.

If sound insulation is required, high-efficiency sound insulation materials can be installed on the inside of the aluminum plate.

High-rise buildings such as exterior walls, beams, balconies, canopies, airports, stations, hospital conference halls, reception halls of opera houses, stadiums, etc.