China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Metal honeycomb is a new type of functional composite material composed of metal skeleton and honeycomb pores, which is named because its internal structure contains many honeycomb through holes. The aluminum honeycomb core is made of multiple layers of aluminum foil bonded, pressed, and then stretched into a regular honeycomb shape.

由于aluminum honeycomb panelThe special structure of the core, which is divided into many closed cells, limits the flow of air in the curtain wall panel synthesized by it, greatly restricts the propagation of heat and sound waves, and has good heat insulation, sound insulation, electrical conductivity, heat resistance and corrosion resistance, energy absorption and shock absorption, and heat preservation effects. At the same time, its bending resistance, compression resistance and light specific gravity characteristics also make other building materials incomparable. As the aristocrat in the honeycomb family, aluminum honeycomb has very excellent performance. It has high strength, high temperature resistance and corrosion resistance. It is an ideal material for aviation, aerospace, high-speed ships, high-speed trains and other industries. It is a large-size curtain wall in the construction industry. And the preferred material for indoor luxury decoration with high flame retardant requirements.

At the same time, due to the decline in the price of carbon fiber and aromatic polyphthalamide fiber reinforcement, the variety and quality of polyester, epoxy and thermoplastic resins are increasing, which provides favorable conditions for the development, application and development of more new varieties of sandwich composite materials. In sandwich structures, polymer foam is one of the most commonly used core materials. Mainly include: polyvinyl chloride (PVC) foam, polystyrene (PS) foam, polyurethane (PU) foam, polymethacrylimide (PM]) foam, polyetherimide (PEI) foam and acrylonitrile styrene (SAN or AS) foam and other four. 1 structure of aluminum honeycomb core

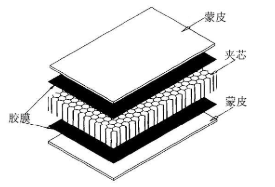

Aluminum honeycomb sandwich structure composite material is composed of two high-strength upper and lower skins (also known as panels depending on the use environment) and a thick and light sandwich layer between them. Schematic diagram of its structure is shown in Fig.