China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum honeycomb panel ceiling nodeExcellent surface coating performance. High-quality aluminum gusset plate is generally made of high-quality paint, which is coated by imported full-automatic high-speed coating line. The surface of the plate is flat, has no color difference, has strong coating adhesion, can resist the erosion of acid, alkali and salt spray, does not change color for a long time, and does not fall off. Fluorocarbon coated plate is an extremely ideal decorative material for outdoor use, with a service life of more than 20 years and convenient maintenance.

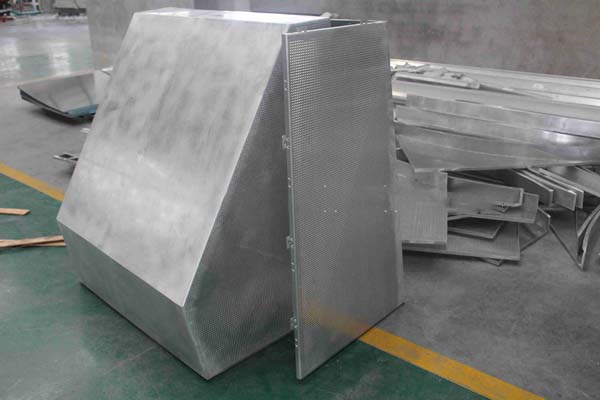

The aluminum gusset plate has a flat surface and clear ridges. The ceiling system reflects the appearance effect of neat, generous, rich and elegant, and wide vision. The aluminum gusset plate has the advantages of flame retardant, anti-corrosion and moisture-proof, and is convenient to assemble and disassemble. Each plate can be disassembled independently, which is convenient for construction and maintenance.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

If you need to exchange and clean the ceiling panel, you can use a magnetic suction cup or a special plate removal device to quickly take the board, or you can add a layer of sound-absorbing paper or black flame-retardant cotton cloth on the back of the perforated plate, which can reach a certain sound-absorbing standard.

aluminum honeycomb panelThe ceiling node material is easy to process, the processing machine is simple, and can be processed on site: aluminum-plastic plate weighs only about 3.5-5.5kg per square meter, so it can reduce the harm caused by earthquake disaster and is easy to handle. Its superior constructability requires simple woodworking tools to complete various shapes such as cutting, clipping, edge planing, bending into arc shape and right angle, and can cooperate with designers to make various changes, installation is simple and quick to reduce construction costs.

Function top: independent heating lamp, independent lighting lamp and independent ventilation fan can be arranged in reasonable installation positions, thus overcoming the embarrassment of traditional bath heater installation positions. The heating lamp can be installed directly above the shower area, the lighting lamp can be installed in the middle of the room or at the position of the wash basin, and the ventilation fan can be installed directly above the toilet bowl, thus each function can be installed in the most needed space position, with high heat and low consumption, double warm.

With the development of construction industry and the continuous improvement of construction technology, there are more and more high-rise buildings with large space and large span. The construction method of large honeycomb aluminum ceiling with large area is introduced, and the construction technology of large area ceiling with keel installed on the steel truss structure is introduced.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

In order to ensure the stability of the whole steel truss structure, the connection mode of steel keel and truss adopts hoop node plate and bolt connection, which avoids too much welding mode. The elliptical hole on the hoop is designed to be adjustable in the direction along the main steel structure, and the main keel of the suspended ceiling can be adjusted in the height and left and right directions in the long elliptical hole of the node plate.

Recommended:Introduction to the scope of application of punching sound-absorbing honeycomb aluminum plates