China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

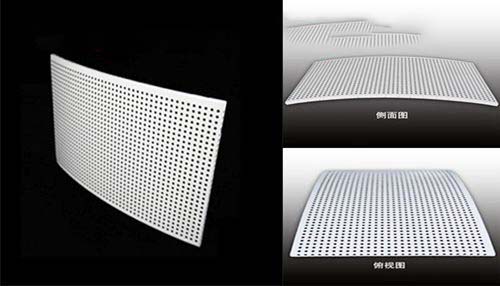

Processing of aluminum honeycomb panelThe aluminum honeycomb panel mainly uses high-quality 3003H24 alloy aluminum plate or 5052AH14 high manganese alloy aluminum plate as the base material. The panel thickness is 0.8~1.5mm fluorocarbon roll-coated board or light-resistant baking varnish. The light-resistant baking varnish is stronger than PVDF in scratch resistance, acid rain corrosion discoloration resistance and self-cleaning properties. The thickness of the bottom plate is 0.6~1.0mm, and the total thickness is 25mm.

The core material is hexagonal 3003 aluminum honeycomb core, the thickness of aluminum foil is 0.04~0.06mm, and the side length is 5~6mm. The forming of the front and back skins is completed by roll forming technology, the edge is folded by full-automatic machinery and equipment, and the front and back skins are tightly occluded at the installation edge.

aluminum honeycomb panelProcessing: The whole processing process of aluminum honeycomb panel is completed in a modern factory. Hot pressing technology is adopted. Due to the high heat conduction value between aluminum skin and honeycomb, the thermal expansion and cold contraction of inner and outer aluminum skin are synchronized. There are small holes in the honeycomb aluminum skin, so that the gas in the plate can flow freely. The sliding installation buckle system of the aluminum honeycomb panel will not cause structural deformation during thermal expansion and cold contraction, so it can ensure extremely high flatness. Adhesive: the two-component polyurethane high-temperature curing adhesive is formed by pressurizing and high-temperature compounding with automatic honeycomb board compound production equipment, which overcomes the brittleness of the bonding layer of honeycomb board in the past.

The inner layer of the aluminum honeycomb panel is a special hexagonal aluminum honeycomb, which is composed of aluminum alloy with a hardness of H19. As a core plate adhered in the sandwich structure, it bears pressure in the tangential direction.

Recommended:The characteristics of aluminum corrugated board and its use.