China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

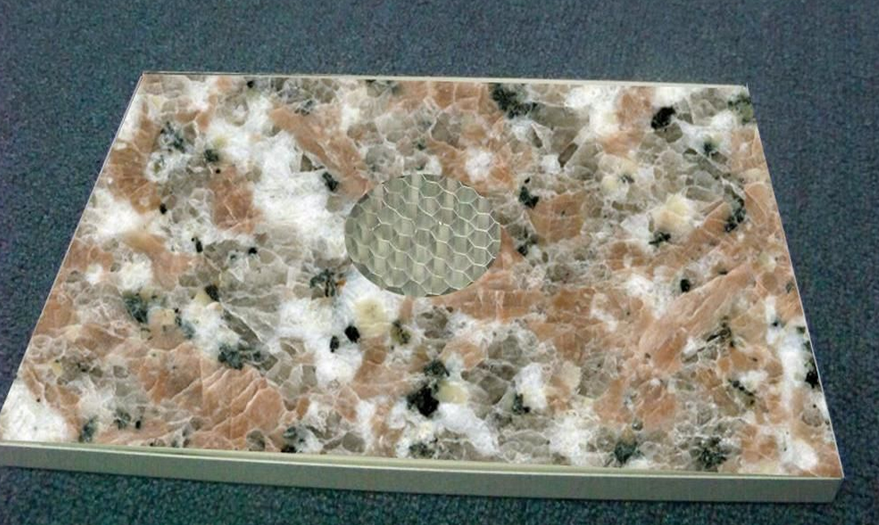

aluminum honeycomb panelDerived from the aviation industry composite honeycomb panel technology, is a typical sandwich structure, consisting of a panel, a bottom plate and an intermediate aluminum honeycomb. Aluminum honeycomb panel product series has the advantages of excellent material selection, advanced technology and reasonable structure. It not only has excellent performance in large scale and flatness, but also has many choices in shape, surface treatment, color and so on.

Aluminum honeycomb panel is one of the modern building materials Products, with high wind pressure resistance, shock absorption, sound insulation, heat preservation, flame retardant and high specific strength excellent performance, is widely used in civil construction, vehicle and ship decoration. Therefore, aluminum honeycomb panels have very high requirements in the production, in order to better achieve the use effect. Today Xiaobian for everyone to organize the introduction of aluminum honeycomb panel in the processing process of the details:

1. The material of aluminum honeycomb panel decorative panel is generally selected from 3003, 5005 and other brands, and the 1100 plate with low alloy composition is less used. Decorative surface by spraying or roller coating form, coating for polyester or fluorocarbon paint, exterior wall board is best choice of spraying board, and requires more than three coating, paint layer thickness ≥ 40μm, so as to ensure the durability of the coating.

2. The aluminum honeycomb panel needs to undergo strict surface anodization treatment before painting to ensure sufficient coating adhesion and bonding strength with the honeycomb core. The panel coating should meet the requirements of the national specification YS/T429.2-2000.

3. Compared with aluminum veneer, the maximum plate surface of box-type honeycomb aluminum plate can be 500mm × 4500mm, because the plate itself is made of composite material, and the internal aluminum honeycomb provides guarantee for the plate itself to bear its own weight, so that the plate itself does not need to add any reinforcing ribs. However, when the width of ordinary aluminum veneer is greater than 1m or the length is greater than 2m, stiffeners must be added behind the plate. The stiffener needs to be welded on the back of the board, because the thermal expansion coefficient of the stiffener is different from that of the board itself. After several cold and hot changes, the front of the board will appear uneven. And this phenomenon usually starts to appear half to one year after the completion of the project.