China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

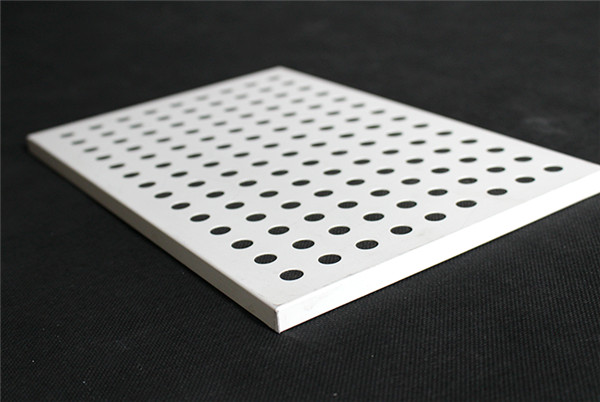

Punched aluminum veneer是众多铝单板产品之一,下面来看看它的生产加工工艺。Punched aluminum veneerCompared with ordinary aluminum veneer, it is a punching process. Do not underestimate this process. For example, the size of the punching hole, the size of the vacancy, the punching rate, whether it meets the design requirements, the position of the punching hole, etc. If there is no special design in advance, the aluminum veneer that looks beautiful will easily produce errors and affect the effect.

Therefore, punching this seemingly simple processing technology is impossible. In the conventional aluminum veneer processing process in order to open, draw lines, bending, welding, grinding, installation angle, polishing, pretreatment, painting and other processes. The punching process of punching aluminum veneer is to draw the line, according to the position of the hole on the design drawing, and then use the CNC punching machine to carry out relevant operations to meet the corresponding design requirements.

Characteristics of punched aluminum veneer

1. Punched aluminum veneer can be customized according to needs to meet the personalized needs of customers;

2. The installation and construction of punching aluminum plate is convenient and fast. After the plant is processed and formed, the construction site does not need to be cut, as long as it is fixed on the skeleton, the installation and maintenance are simple and flexible, which greatly reduces the installation and maintenance costs;

3, not easy to dirt, conducive to cleaning and maintenance, non-cementing fluorocarbon material film, making the surface is difficult to adhere to pollutants, and has a good to clean;

4, punching aluminum skin can also reduce noise;

5, light weight, strong plasticity, good durability, environmental protection can be recycled and other main features, aluminum plate yield of 100, green environmental protection, in response to the national call for creation. Durable, quality assurance.